Sand Boil Filter

Lightweight filter kit simplifies sand boil treatment

to speed remediation

Caused by the pressure from rising water levels, a sand boil is an eruption of water bubbling out of a hole in the ground surrounded by a mound of displaced soil. They are a visible symptom of internal erosion under a levee, also called backward erosion piping, which is responsible for 46% of levee failures. If the sand boils are not treated immediately, they will grow and displace more sediment, increasing the risk of a catastrophic breach.

The current method to treat this erosion is difficult, expensive, and dangerous. To reduce the pressure and slow or stop the erosion, sandbags are used to construct a ring around the boil to allow the spewing water to pool. As the water level within those sandbags increases, the pressure across the levee system is reduced. It requires hundreds of 35-pound sandbags and can take a four-person team six to eight hours to control a medium-sized sand boil. It is dangerous work that also exposes the laborers to a potential levee failure.

This new lightweight filter kit simplifies this cumbersome and dangerous process by allowing field personnel to quickly establish and adjust the hydraulic head within a sand boil to relieve pressure and halt erosion. The filter is inserted into a sand boil to provide pressure relief similarly to the sandbags. It increases the water level at the insertion point (the exit location) and decreases the pressure gradient across the levee system, stabilizing the foundation material.

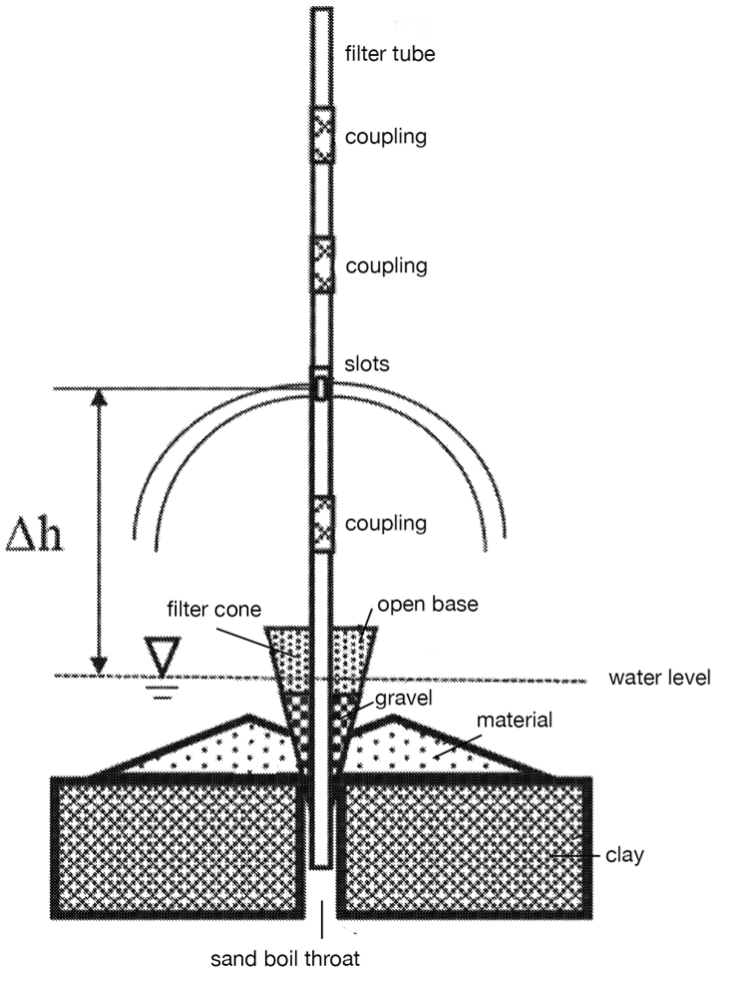

ERDC’s sand boil filter combines a conical filter with a PVC pipe through its center. The filter cone is placed within the sand boil, creating a seal, and forcing water upward through the center pipe. This setup allows the user to control the exit height of the water—and therefore the hydraulic head—by adjusting the height of the pipe openings. The pressure is reduced, which stops the erosion at the pipe tip under the structure.

These filters prevent sand boils from growing, while relieving the underground hydrostatic pressure that created the sand boil and inhibiting subterranean erosion that can cause failure of a nearby levee.

The lightweight filter can be installed by a single worker in 15 minutes or less, making it faster, cheaper, and less labor-intensive. This allows personnel to alleviate multiple sand boils more quickly and effectively and get out of danger, thereby protecting the critical levee systems and the people downstream.

Benefits:

- Less labor intensive: The filters can be installed by a single person rather than requiring a team of people.

- Faster: Unlike the 6–8 hours to install sandbags, the filter kits can be installed in about 15 minutes — speeding the release pressure in the levee. Installing a kit in a medium-sized sand boil is 47 times faster than using sandbags.

-

More effective: The conical filter’s larger effective surface area is less susceptible to clogging and, therefore, promotes the flow of water out the top of the sand boil. This reduces the underground water pressure more effectively, while also inhibiting the creation of additional sand boils nearby.

-

Cheaper: The sand boil kits cost about $200 and come with installation tools and replacement parts. After the first use, the reusable kits are estimated to be 114 times cheaper than using sandbags.

- Safer: Installing the kits reduces the time workers and people downstream are exposed to a potential levee failure as well as speeds up the pressure reduction in the levee.

- Lightweight and portable: The kits are easy to handle, and several kits and the included tools and parts can fit in the back of a pickup truck.

Applications:

- Designed for quickly treating sand boils that appear as a result of internal levee erosion in order to slow or prevent it from growing or further eroding sediment

Patents

- 10519617 (Search patent)

- 11745122 (Search patent)