Modular Bathymetry

Bathymetric Modeling Method with

Computer Numerical Control (CNC) Programming

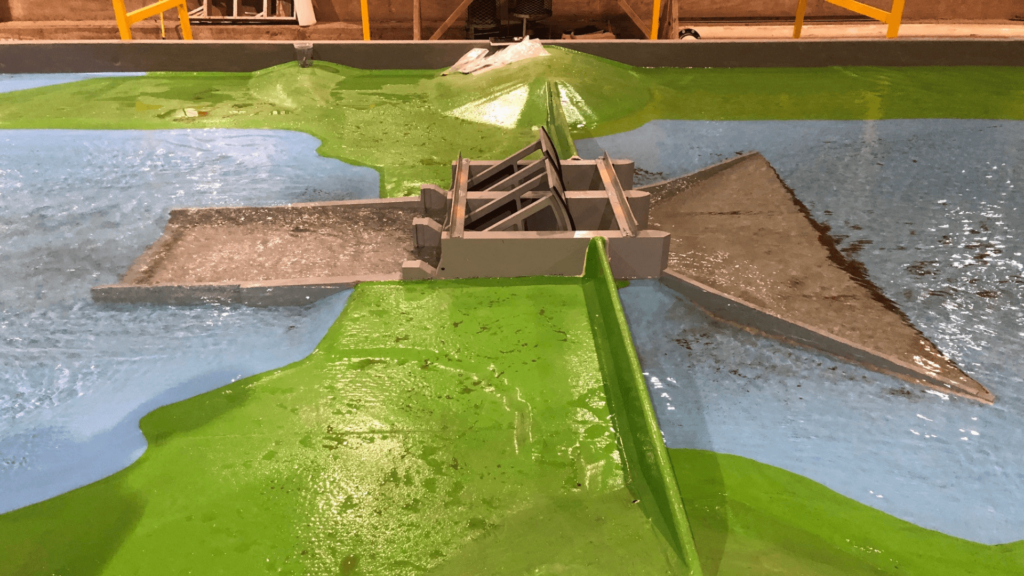

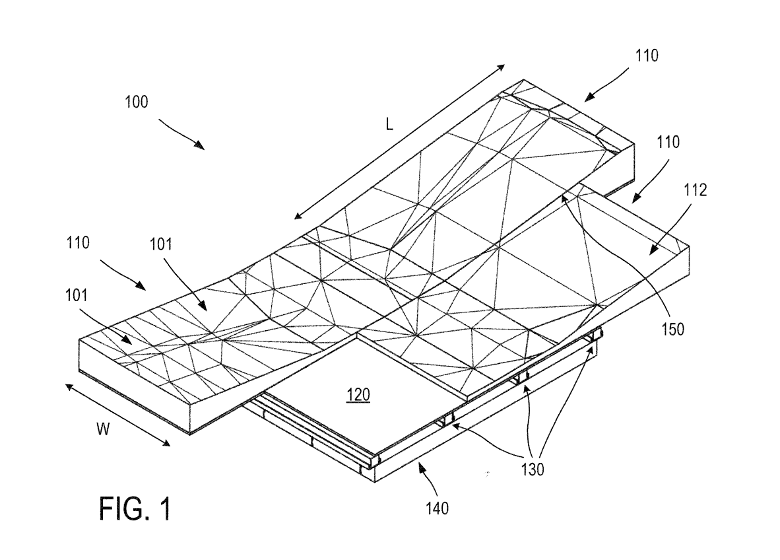

This new approach to bathymetry modeling seeks to revolutionize the building process with lightweight, modular blocks that are digitally routed via distinct Computer Numerical Control (CNC) programming from expanded polystyrene foam (EPS). The resulting model achieves a level of precision unattainable with concrete modeling. The technique and materials allow rapid production and construction as well as reproducibility with less labor, which builds on the cost savings. The EPS blocks are lightweight and maneuverable; therefore, they are easily stored. Yet, if storage is limited, the method’s on-demand model production capability diminishes the need for long-term storage. The flexibility of this system to make quick modifications is critical for ongoing prototype refinement. These bathymetric modeling innovations result in a more detailed, accurate, user-friendly model with significant labor and material cost savings.

Historically, bathymetric modeling—the mapping of underwater terrain for numerous applications in freshwater and marine environments—has utilized concrete as its construction material. This process is time-consuming and costly due to labor requirements and materials. While strong and durable, the physical characteristics of concrete prohibit modularity and reproducibility and may produce models that lack a high level of accuracy. A need exists for a modeling system that is more accurate, flexible, and easily modifiable, with lower construction and labor costs.

Benefits:

- Less expensive: Using EPS as the primary construction material has reduced construction costs by 30-60% compared with labor-intensive concrete modeling.

-

More precise: Distinct Computer Numerical Control (CNC) programming is used to digitally form expanded polystyrene foam (EPS) blocks that can be easily manipulated to create more detailed and accurate bathymetric models than traditional concrete modeling methods.

-

Modular: EPS foam blocks can be easily and rapidly placed and removed in situ, allowing prototype refinement, use in limited space areas, and storage.

-

Lightweight: EPS blocks are lightweight, making them easy to maneuver in construction, testing, removal, and storage.

-

Reproducible: CNC programming allows prototype recreation, removing the need for long-term storage, if desired.

-

Flexible: Original block designs can be easily modified with CNC programming, allowing multi-scenario testing.

-

Efficient: This modular system allows significantly faster construction time – up to 60% in applications.

Applications:

- Bathymetry applications: Flood control, Hydropower systems, Dam removal, Lock systems, Wave and coastal environment modeling

- Automotive parts

- Heating, ventilation, air conditioning, and refrigeration (HVAC-R) components

- Construction industry

- Pharmaceutical and medical industry

- Appliance packaging

- Food industry

- Horticultural industry

- Seating apparatus: Automotive, Lightweight aircraft, Designer, Event, Wheelchair

- Prototype creation

- Miscellaneous: Modular furniture, surfboards

Patents

- 12046150 (Search patent)

Resources

- Rough River Outlet Works Physical Model Study

- ERDC R&D publication

- Needs and Opportunities for Testing of Hydropower Technology Innovations