Hydrogel-Enzyme Systems and Methods

Perform bioreactions for cleanup in harsh conditions

Enzymatic activity is most effective under ambient conditions—but those conditions are not always present in situations where bioactivity is needed most urgently, such as clean up in industrial settings. A protective vehicle is needed that will enable enzymes to remain active under harsh conditions, or after being subjected to harsh conditions, such as extreme heat, pH, or in the presence of denaturing chemicals.

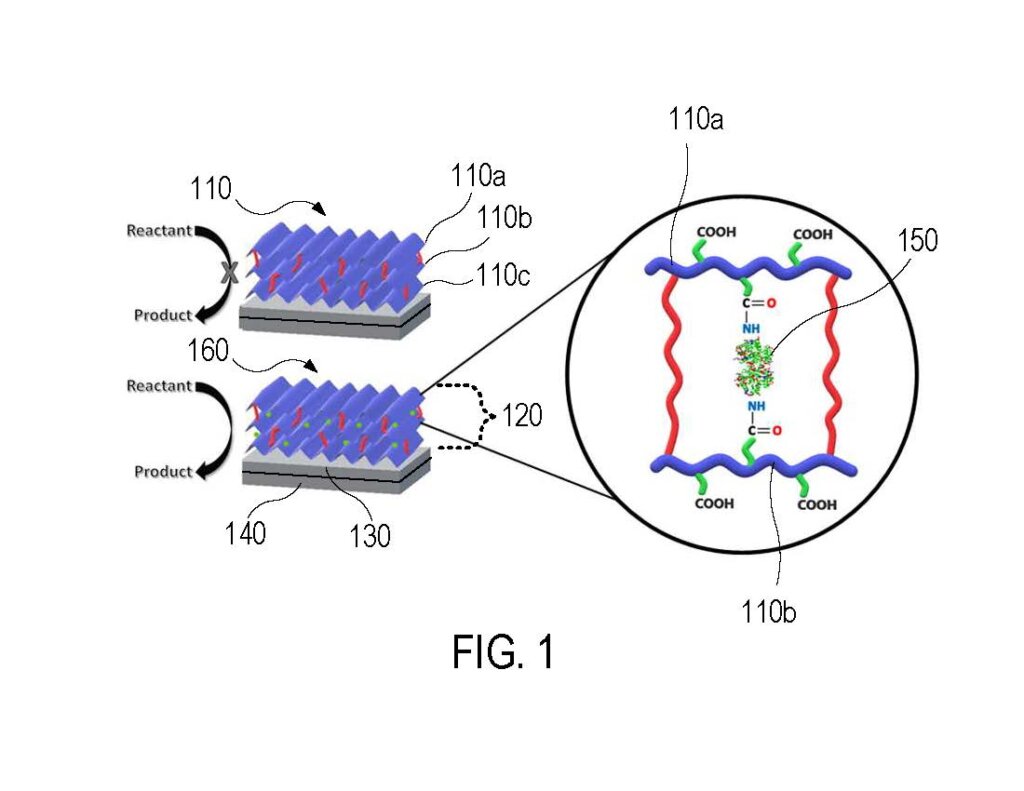

This hydrogel is designed to provide a stable medium to prevent enzyme denaturation at high temperature, extreme pH levels, and damage from harsh chemicals. The hydrogel embeds enzymes between protective layers of poly(methacrylic acid) (PMAA) and chemically bonds the enzymes to these layers. The layers of PMAA act as a protective framework that safeguards the enzymes and preserves their biological activity. With this protection, the enzymes may be deployed in more extreme conditions, or with more flexibility in a processing assembly line. This will save time and reduce the risk of harmful exposure to personnel and sensitive equipment in contaminated or hazardous environments, such as industrial clean-up or polluted systems.

Benefits:

- Versatile: Designed to protect different types of enzymes under varying conditions

- Stable: Designed to withstand a wide range of external conditions such as high heat and extreme pH

- Protective: Increases flexibility to introduce the bioactivity, such as before temperatures cool, potentially reducing risk of harmful exposures for personnel and sensitive equipment entering a site

- Time-Saving: Potentially saves time by allowing teams to begin bioprocessing without waiting for ideal conditions for enzyme performance

Applications:

- Industrial sites

- Controlled detonations

- Wildfires

- Chemical spills

- Brownfields

- Airports

- Processing lines

Patents

- 12098272 (Search patent)