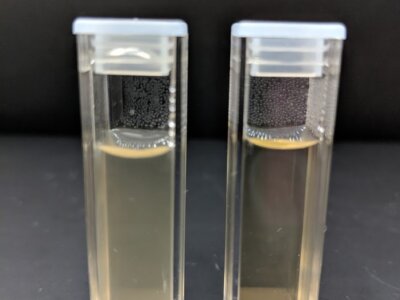

Self-Regenerating Biofilter

• External maintenance via human intervention not required

• Shorter downtime leads to an estimated 10x decrease in operational costs

• Offers scalability via a compact footprint for continuous water treatment and higher daily flow-through volumes