Carbon Nanotubes Engineered for Stability and Scalability

Scalable, Non-Destructive Biological Fabrication Method for Single-Wall Carbon Nanotubes (SWNTs)

Carbon nanotubes (CNTs) — particularly SWNTs — have exceptional mechanical, thermal, and electrical properties, making them ideal for numerous applications. However, their practical use is limited because of poor solubility and a tendency to aggregate, which makes them difficult to align and form into larger structures. There are currently no efficient methods for assembling CNTs, and existing chemical approaches often damage their desirable properties.

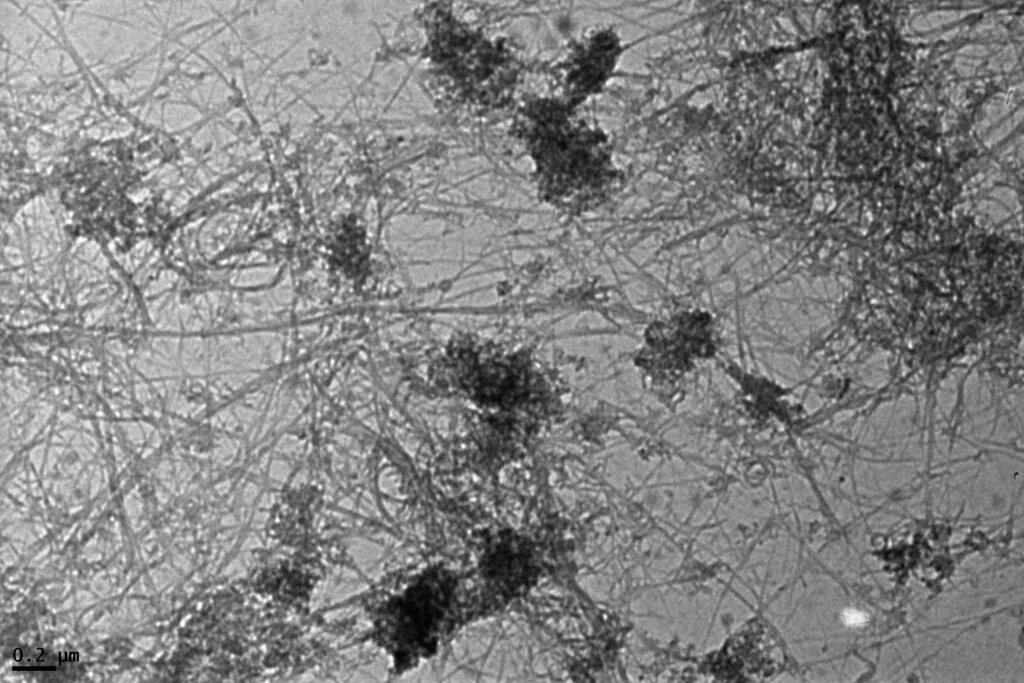

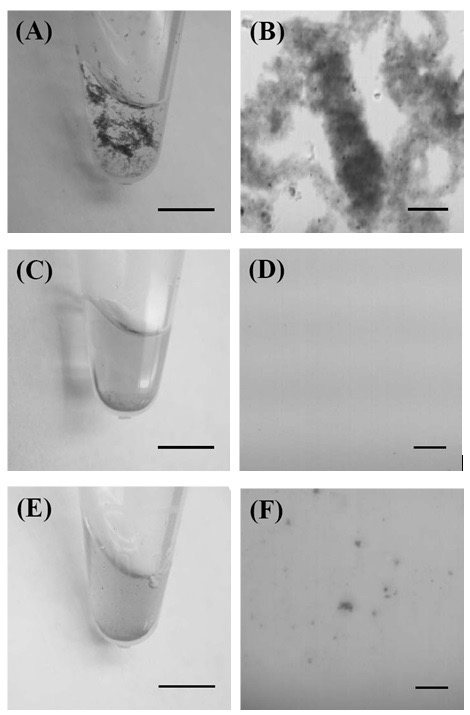

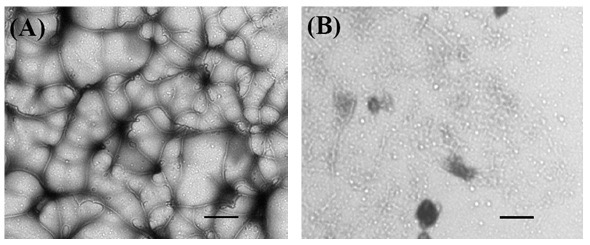

This technology uses a biological fabrication method to assemble carbon nanotubes into visible structures—without damaging them. Ultrasonication is used to wrap short DNA strands around SWNTs, making them more water soluble and stable. The reaction takes place in a heated water bath at 60°C, using adenosine triphosphate (ATP) as an energy source and DNA ligase as the enzyme catalyst. The DNA ligase links DNA strands from different nanotubes, effectively cross-linking the nanotubes through their DNA coatings.

This process results in millimeter-sized aggregates that are visible to the naked eye and enables scale-up from nanoscale individual tubes to macroscopic structures. The structures can be selectively disassembled using the DNase I enzyme, which cleaves the DNA linkages, reducing aggregate size by 100-200-fold.

This biological fabrication method enables direct assembly of CNT-based nanostructures.

Benefits:

- Non-Destructive: Uses non-covalent DNA binding to preserve the CNT properties

- Controllable and Reversible: Provides precise control over assembly

- Water-Based: Is an environmentally friendly option.

- Versatile: Can be used to aggregate any type of CNTs

- Thermal Management: Offers excellent thermal conductivity

Applications:

- Structural Materials

- Flexible Electronics

- Mechanical Components

Patents

- 10526628 (Search patent)