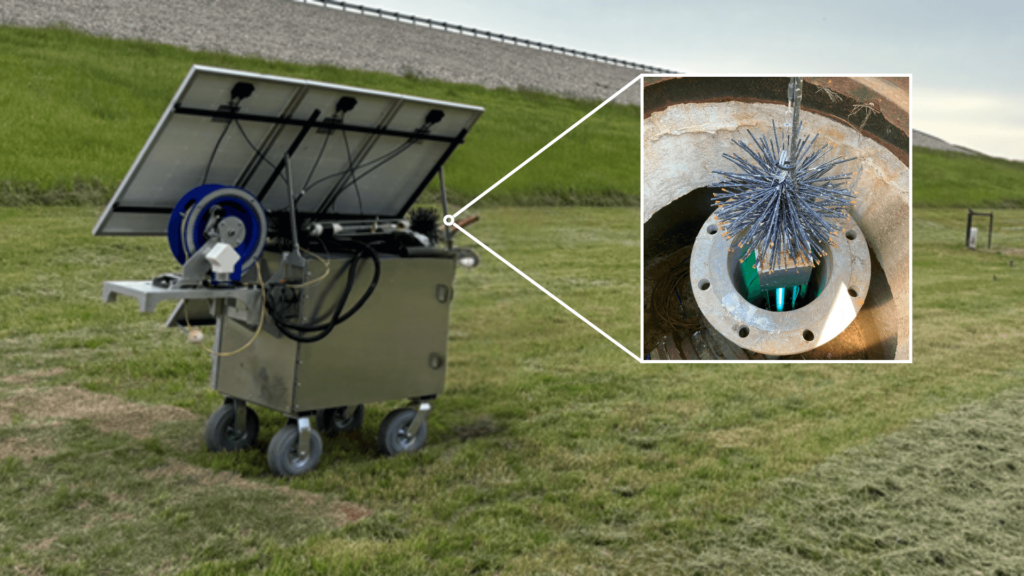

Autonomous UV and Brush Apparatus for Well Fouling Prevention (Wellbot)

Autonomous System Offers Innovative Method for Relief Well Cleaning and Maintenance

As integral elements of earthen dams, levee systems, and other hydraulic structures, relief wells function as first-line defenders of potential failure, maintaining structural integrity by relieving hydrostatic or uplift pressures beneath structural elements.

Current cleaning (de-fouling) methods to remove mineral scale and biofilm buildup are costly, risky, and largely ineffective. Efforts costing $10,000 per well often achieve only a limited (3-5%) improvement in well function. Hazardous chemicals and heavy equipment threaten the safety of personnel deploying the treatments.

Wellbot tackles the critical issue of mineral and biofilm deposits that restrict waterflow in a well, leading to undesirable increases in subsurface pressure. It comprises a rugged, wheeled cart featuring integrated solar panels, batteries, programmable autonomous systems, satellite internet connectivity, and a reel-mounted sanitizing unit. Employing UV-C light sterilization and powerful brushes, the cleaning system offers dual-action mechanisms for safe and effective decontamination.

Individual cleaning cycles, adjusted for well depth, take approximately 20 minutes each and occur over a 15-hour daily operation during a programmed, one-week cleaning regime. Proactive, routine well maintenance may be performed using faster reel speeds and shorter cleaning cycles. Embedded solar power, electrical backup, and satellite internet connectivity create a true, autonomous “set-it and forget-it” system.

A single, non-technical individual may deploy Wellbot in approximately 30 minutes and, after the cleaning operation is complete, easily relocate the nearly 200 lb. Wellbot to the next relief well site. With an approximate construction cost of $5,000 and a multi-year lifespan, Wellbot offers a less expensive, less risky alternative that bypasses the need for chemicals, heavy machinery, and excess manpower.

Benefits:

- Safer: Eliminates the need for hazardous chemicals and heavy machinery, providing a safer working environment.

- Less expensive: Costs half of current per-well cleaning methods and can be used at hundreds of wells over its multi-year lifespan.

- Quicker: Sets up in 30 minutes without technical know-how.

- Autonomous: Functions independently during its cleaning regimen after initial set up.

- Remote connectivity: Enables remote monitoring and adjustment with on-board satellite internet equipment.

- Low maintenance: Requires minimal power, maintenance, and mobilization effort.

Applications:

- Relief well cleaning

- Preventative relief well maintenance

- Predicted high-water event management

- Enhanced in-situ bioremediation

Patents

- 20250101833 (Search patent)